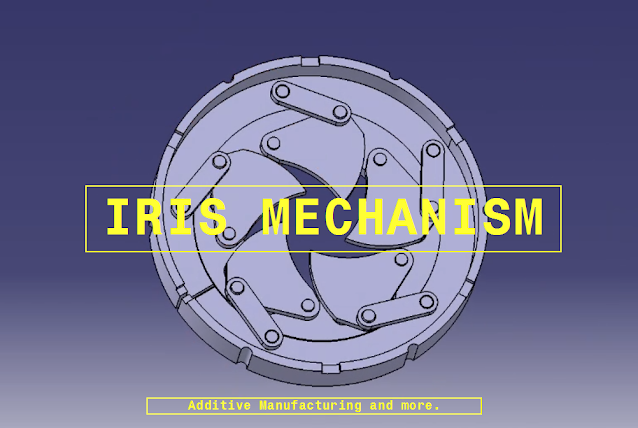

Iris mechanism : Additive manufacturing and more

Hello people, this is Ruturaj Lonkar (B.E. Mechanical). Recently I was working on a cool project for my bike. I have designed and manufactured an IRIS to cover my bike's keyhole. It is just an aesthetic piece of engineering to make me feel good while using it. Design : I started with all the basic measurements from my bike related to keyhole diameter, height etc. And further I studied the basic working of iris mechanism and iterated some models in CATIA V5 . With help of assembly workbench of CATIA I was also able to manipulate and actual see the functioning of the mechanism and also check for any CAD related collisions. After few iterations i got the mechanism right. Now it was time to make changes for manufacturability. Manufacturing: I had to also consider manufacturability of the product so that I don't face any issue. The design was coming along great but manufacturing it through conventional subtractive method of manufacturing would have cost me alot and also wo...