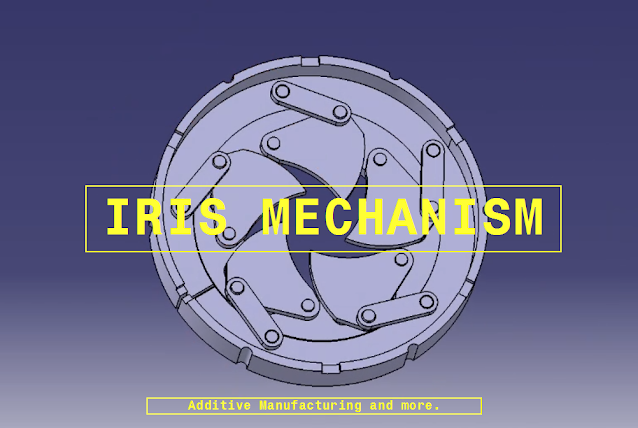

Iris mechanism : Additive manufacturing and more

Hello people, this is Ruturaj Lonkar (B.E. Mechanical). Recently I was working on a cool project for my bike. I have designed and manufactured an IRIS to cover my bike's keyhole. It is just an aesthetic piece of engineering to make me feel good while using it.

Design :

I started with all the basic measurements from my bike related to keyhole diameter, height etc.

And further I studied the basic working of iris mechanism and iterated some models in CATIA V5

And further I studied the basic working of iris mechanism and iterated some models in CATIA V5

.

After few iterations i got the mechanism right. Now it was time to make changes for manufacturability.

Manufacturing:

I had to also consider manufacturability of the product so that I don't face any issue. The design was coming along great but manufacturing it through conventional subtractive method of manufacturing would have cost me alot and also would have been very complex process.So I decided to go with 3D printing. I manufactured these with FDM printing using PLA as material.

Even though my CAD model had small geometrical features the printer got them right. (I had some small extrusions of about 2 mm diameter)

(Pro tip: While exporting STL from CATIA for 3D printing change graphic view accuracy to 0.01, it makes your curve more round or else you would end with small edges like a polygon instead of curve.)

I made use of Ultimaker Cura software for slicing the model for 3d printing.

Had to do some iterations of printing to get the tolerance right and compensate with machine inaccuracies.

But the results were totally worth it.

But the results were totally worth it.

Result :

I was able to manufacture and assemble the mechanism as desired and then I installed it on my bike.

Conclusion :

I am super satisfied with the results and I am amazed by what amount of power a designer holds with introduction of additive manufacturing.Manufacturing critical shapes and mechanisms has become alot easier.

Just imagining the future of this technology when it gets more easier and overcomes its current flaws makes me astound. Their are endless possibilities to this method of manufacturing and opens new doors for manufacturing flexibility.

Just imagining the future of this technology when it gets more easier and overcomes its current flaws makes me astound. Their are endless possibilities to this method of manufacturing and opens new doors for manufacturing flexibility.

That's all for now. Do tell me about your thoughts on this.

Thanks for reading.

Contact at:

@ruturajlonkar on Instagram

Or

ruturajlonkar10@gmail.com

Comments

Post a Comment